RIVARD’s story begins at the start of the 1950s with a dealership for the iconic Mercedes UNIMOG, multi-function vehicles. RIVARD’s geographical location in a rural area with significant agricultural activity encouraged the company to develop agricultural machinery. Increased skills opened up the national market and expanded the company’s areas of activity.

Since the end of the 1960s, RIVARD has been specialising in sanitation equipment and more particularly in 12t to 32t hydrocleaning units. We offer a wide range with a great choice of suction power and high pressure levels, along with a host of tank volume possibilities with fixed or mobile walls. All RIVARD products are designed around certain principles: safety, hygiene, ergonomy and ease of maintenance.

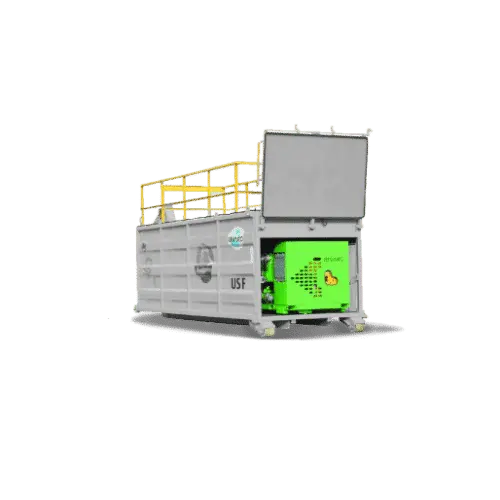

How a hydrocleaning unit operates

A hydrocleaning unit truck is also often called a combined or mixed cleaning truck. In fact, this type of truck is most often equipped with a High Pressure pump for cleaning operations and also a vacuum pump to suck up waste and bring it into the tanker. This tanker is divided into at least 2 compartments: 1 to store clean water (placed at the front) and to receive the sludge (placed at the rear of the tank). The waste is evacuated through the drainage valve or by lifting the tanker and opening the bottom. RIVARD has also provided more flexibility in the use of its cleaning trucks by proposing a partition that can be moved inside the tanker and so adapt the volume distribution during operation. The water compartment is maximised at the start of the round and is reduced in size to leave room for sludge at the end of the day.

The truck composition

RIVARD’s experience in assembling hydrocleaning units or sanitation combination units provides a wide choice of reference carrier chassis (RENAULT, SCANIA, MAN, MERCEDES, VOLVO, DAF, IVECO, etc.) for numerous tonnage levels and configurations. Once the chassis is delivered, we install the technical platform that accommodates the pumps and use the carrier’s energy to supply all the components. Finally, we install the tanker with the hydraulic lifting system up to 65°.