RIVARD’s story begins at the start of the 1950s with a dealership for the iconic Mercedes UNIMOG, multi-function vehicles. RIVARD’s geographical location in a rural area with significant agricultural activity encouraged the company to develop agricultural machinery. Increased skills opened up the national market and expanded the company’s areas of activity.

Since the end of the 1960s, RIVARD has been specialising in sanitation equipment and more particularly in 12t to 32t hydrocleaning units. We offer a wide range with a great choice of suction power and high pressure levels, along with a host of tank volume possibilities with fixed or mobile walls. All RIVARD products are designed around certain principles: safety, hygiene, ergonomy and ease of maintenance.

How a hydrocleaning unit operates

A hydrocleaning unit truck is also often called a combined or mixed cleaning truck. In fact, this type of truck is most often equipped with a High Pressure pump for cleaning operations and also a vacuum pump to suck up waste and bring it into the tanker. This tanker is divided into at least 2 compartments: 1 to store clean water (placed at the front) and to receive the sludge (placed at the rear of the tank). The waste is evacuated through the drainage valve or by lifting the tanker and opening the bottom. RIVARD has also provided more flexibility in the use of its cleaning trucks by proposing a partition that can be moved inside the tanker and so adapt the volume distribution during operation. The water compartment is maximised at the start of the round and is reduced in size to leave room for sludge at the end of the day.

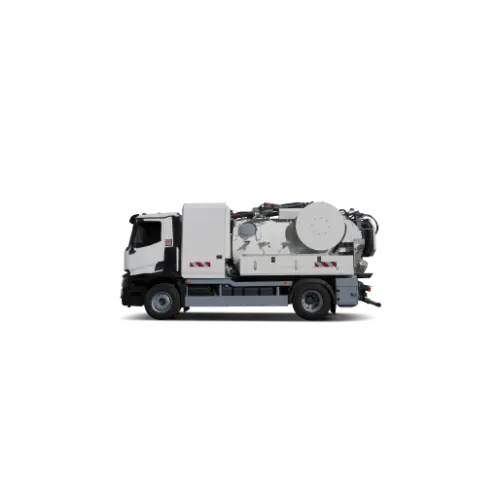

The truck composition

RIVARD’s experience in assembling hydrocleaning units or sanitation combination units provides a wide choice of reference carrier chassis (RENAULT, SCANIA, MAN, MERCEDES, VOLVO, DAF, IVECO, etc.) for numerous tonnage levels and configurations. Once the chassis is delivered, we install the technical platform that accommodates the pumps and use the carrier’s energy to supply all the components. Finally, we install the tanker with the hydraulic lifting system up to 65°.

RIVARD presents its dedicated vehicles for cleaning and emptying septic tanks

Most RIVARD equipment can be used to clean and empty septic tanks. Non-collective sanitation (NCS) accounts for nearly 25% of the sector. Millions of structures are not connected to the collective network and this is even more the case in rural areas. Cleaning, emptying and pumping out septic tanks present their own challenges (access often difficult, large volumes, environmental standards, etc.). RIVARD has created dedicated trucks which are more adapted to septic tanks: the CLEANFOS and ZEPHYR.

The important factors in emptying septic tanks

It is vital to maintain your septic tank (cleaning, emptying, pumping, clearing) to ensure the sanitation system operates correctly and to prevent any unpleasant odours rising to the surface or even gases being created.

There is no exact frequency for when you should empty your septic tank. The law recommends emptying septic tanks every 4 years, but this depends on its size and how often it is used. It is recommended that the level be checked regularly.

The first crust must not exceed half of the tank. If the tank is over 50% full, you should call on a cleaner equipped with a RIVARD hydrocleaning unit.

The method which involves pouring water into the tank and only collecting the residual sludge is ideal for the environment, standards and ANC recommendations. It also enables water to be saved and bacteria to be added.

Vehicles and equipment dedicated to septic tank maintenance

Contrary to what we may think, the tank doesn’t need to be empty when the cleaner leaves. For environmental reasons, we need to avoid consuming water, and so it is highly recommended to re-use the water that had previously been extracted from the tank; in fact, it is already rich in bacteria. This means that we don’t need to restart a new cycle. It also prevents the cleaner from leaving with a hydrocleaning unit which is full of water. The cleaner can then service more tanks in one round and so save on fuel and help the environment. RIVARD has developed a process to conserve the tank water while the sludge is sucked out and during the septic tank cleaning operation. The enriched tank water is then injected back into the tank.

Our vehicle models

RIVARD proposes a wide range of trucks for septic tank work, with multi-purpose hydrocleaning units or dedicated hydrocleaning units. The multi-tank design and the functions associated with the CLEANFOS and ZEPHYR mean that this equipment is ideally suited to cleaning, pumping and clearing septic tanks. This equipment guarantees high levels of productivity, meaning direct savings. Up to 8 tanks can be serviced without adding clean water. This sludge treatment capacity means that treatment costs per m³ can be divided by a factor of 4 by reducing trips to the treatment plant.