RIVARD does its utmost for the safety of operators.

The constructive solutions adopted by the RIVARD company are in perfect harmony with the ATEX 2014/34 / EU directive, namely: to eliminate the probability of the appearance of an explosive gaseous atmosphere around the equipment and to eliminate the sources of ignition.

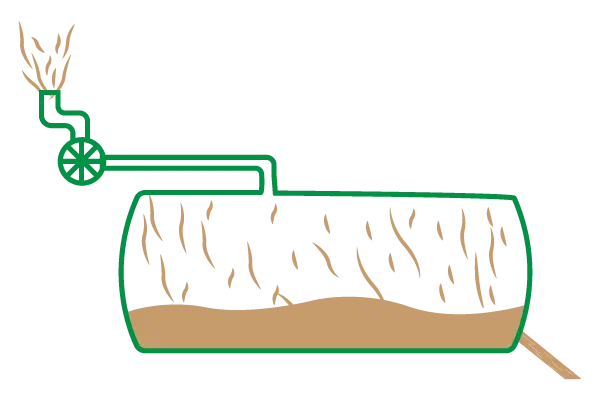

The RIVARD equipment does not generate ATEX in the immediate periphery and this in the different working configurations. Thanks to the entire tank and its sealed and thanks to the proven pumping circuit, there are no uncontrolled gas releases. In addition, the sources of releases are forced out of the material template. The pumping circuit can be connected to an ATEX zone (vehicle parked outside the zone).RIVARD equipment complies with the recommendations of the French health insurance and the Ministry of Labor. They fully comply with the Machine Directive which provides for the normally foreseeable use of the equipment, such as the use of HP when pumping and the safe unloading of ATEX products (carrier on).

The RIVARD ADR/ ATEX range allows the following applications :

LIQUID WASTE PUMPING

LIQUID WASTE TRANSPORT

HEAT EXCHANGER CLEANING

SEWAGE IN SEVESO ZONE

HYDROCARBON SEPARATOR MAINTENANCE

PITS JETTING

Our recognized ADR/ATEX approach

ADR

ADR stands for :

« Accord for Dangerous goods by Road »

This regulation mainly takes into account the container for the transport the product.

ATEX

ATEX is an abbreviation

for « Explosive Atmosphere ».

It is also the short name of European Directive 2014/34/EU